CHAIN COUPLINGS

Our PRODUCT

Lorem ipsum dolor sit amet, consectetur adipiscing do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Can be connected and separated without moving the equipment by winding the chains over and removing them from the sprockets.The coupling provides outstanding durability with the torque distributed to the strong roller chains and surface-hardened sprocket teeth.Can be connected and disconnected by simply inserting and extracting a single roller chain joint pin.

For use in harsh environments where previous steel roller chain couplings could not be used.Main applications water gates, food equipment (fermented and brewed foods), trimming equipment, etc.Double Roller Chain Flexible Shaft Coupling Sprockets in Hardened Steel with Stock Bore for re-boring, to 5″ maximum bore in a variety of sizes from – No. 40 through No. 120 chain.

We provides a broad line of chain couplings, available with finished bore, reborable, and Taper-Lock bushed flanges. A compact design utilizing hardened tooth sprockets and ANSI standard double width roller chain allows the our Chain Coupling to provide excellent torque and bore capacities. Chain assemblies are connected with a link pin, allowing for easy installation or removal.

Metal-Grip Coupling

- Self Anchoring

- Resist Axial Force

- Detachable

- Reusable

- Joins any Metal Pipe

- Ultimate Pull-out Resistance

Grip-L Coupling

- Self Anchoring

- Resists Axial Force

- Detachable

- Reusable

- Joins any Metal Pipe

- Standard Duty Coupling

OPEN-FLEX Coupling

- Wrap-around Design for

Easy Access - Also Suitable for Repairs

Permanent or Temporary - Reusable

- For Pipes with Anchor Points

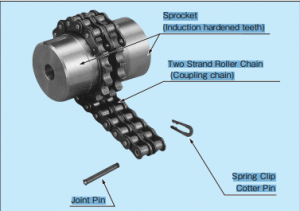

Roller Chain Couplings

Outstanding Durability

The coupling performs outstanding durability with

the torque on the coupling shared with the surfacehardened teeth of the sprockets and the powerful

roller chains that engage with the teeth.

Easy Coupling and Decoupling

Both shafts can be easily coupled or decoupled

with a single joint pin inserted into or extracted

from the roller chains.

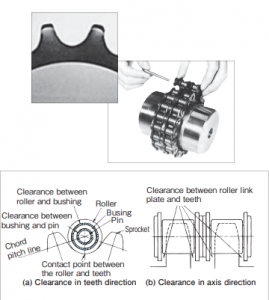

Absorption of Large Misalignment

The clearances between the chains and sprockets

and between chain components absorb the great

positional misalignment of both shafts.

Models in a Wide Variety

A total of 24 models including 15 models

conforming to JIS and 9 other models are

standardized.

(Roller chain shaft joint: Conforms to JIS B

1456-1989)

Body Construction

Body

The body consists of two dedicated

sprockets with hardened teeth and twostrand roller chains. The sprockets are

coupled when the chains are wound around

the sprockets, and decoupled with the chains

removed. Therefore, transmission power can

be coupled or separated without moving the

transmission system.

WARNING

● Install a safety cover and prevent access to any rotating parts: otherwise injury may occur. Set a safety mechanism to stop the

rotating parts when the cover is lifted.

● Transporting, installing, operating, maintaining or inspecting must be carried out by skilled and professional engineers to avoid

mis-handling and hazardous situations.

● When coupling is used with vehicles that carry human, use a device to protect the vehicle: otherwise, accidents and damage

may occur.

● When the coupling is used for an elevator, install a safety device on the elevator in order to prevent it from falling, which can

cause damage and accidents resulting in death or injury.

(Unpacking upon delivery)

● If delivered in a wooden case, unpack with care. Sharp nails may cause injury.

(Additional machining)

● Never modify the coupling; the quality or function of the product may decrease and break or damage the machine or injure the

operator.

(Transportation)

● Never step under the product when it is being elevated for transportation: otherwise, either the poduct or load may fall, causing

accidents resulting in death or injury.

(Installation)

● Wear appropriate clothing and safety gear (safety goggles, gloves, shoes, etc.).

● Make sure the power is switched off, and the machine is completely stopped before installing. Take caution so that the power

does not reconnect accidentally.

● Make sure to tighten and apply sufficient amount of anti-loosening agent to the hexagonal socket head cap screws.

(Operation)

● Avoid contact with any rotating parts ( coupling, shaft, etc. ) during operations. Rotating parts can catch approaching objects

and cause serious injuries.

(Maintenance and inspection)

● Avoid contact with any rotating parts ( coupling, shaft, etc. ) during maintenance and inspection. Rotating parts can catch

approaching objects and cause serious injuries.

● Make sure the power is switched off, and the machine is completely stopped before carrying out maintenance and inspection.

Take caution so that the power does not reconnect accidentally.

Make sure the driving and driven equipment are also completely stopped.

CAUTION

● Do not use coupling beyond its capacity as specified in the catalog. Exceeding its capacity can break the machine and cause

injuries.

● Do not use damaged couplings. They can break your equipment and cause injuries.

(Transportation)

● Pay extra attention so that the equipment will not fall or rollover during transportations.

(Installation)

● Do not touch the edge and inner diameter of any part with bare hands to avoid possible injury.

● Make sure to align the drive and driven shafts as instructed in the manual when installing the coupling.

(Operation)

● Do not touch the coupling during operations to avoid injuries.

● Immediately stop the machine upon any sign of abnormal operation.

(Maintenance and inspection)

● Wear appropriate clothing and safety gear (safety goggles, gloves, shoes, etc.).

● Clean the surrounding area and maintain a clutter-free space to avoid secondary accidents.

● Comply with Ordinance on Labor Safety and Hygiene 2-1-1 general standards.

● Conduct periodic inspections to make sure that the drive and driven shafts are aligned as described in the manual, and that the

rubber and plastic parts are not worn or deformed.

(Environment)

● Coupling scraps should be disposed as general waste by skilled professionals.

● This coupling meets RoHS (Restriction of Certain Hazardous Substances) standards and contains no hazardous chemicals

Visit Today

Visit Us

Santa Fe Avenue, Los Angeles, California, United States