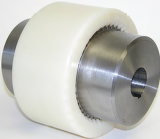

Nylon Sleeve Series Versatile Couplings

The series is really a conventional coupling with two hubs, a nylon sleeve, and retaining rings based upon the model picked. The coupling has a precision molded nylon sleeve and powder metal hub with no bolts, pins, flanges, or protrusions that might have an result on balance or operational security. Given that no lubrication is applied, the couplings can readily be adapted to quite a few applications including vertical and blind installations.

Functions

Compact in size

Upkeep No cost – No Lubrication expected

Can accommodate axial, angular, and parallel misalignment

Simple to assemble

Electrically insulating

Might be utilized in temperature ranges from -25° to 80° C (optional 140° C)

Nylon sleeve has higher resistance to condensation and water, hydrocarbon based mostly petroleums, and alcohols

Not excellent for use with acids, benzyl primarily based products, cresol, or glycols

F Form Flex-Flex Couplings

The F Sort coupling includes two flex hubs, two sleeves and a single accessory kit. This coupling is provided with exposed bolts as common. Shrouded bolts are available upon request via dimension 5.5.

Functions

Patented Vari-Crown? tooth type for extended lifestyle

Conventional 20° pressure angle

Heat treated bolts for better strength

Corrosion resistant bolts and nuts for ease of upkeep

Delivers parallel, angular  misalignment and end float

misalignment and end float

Flex Half coupling interchangeable with market specifications

Ordering Data

Application: Driver and Driven.

Kind and dimension of coupling, horizontal, vertical etc.

Power: Motor horspower or torque necessity.

Velocity: Motor RPM or Driven RPM.

Distance between shaft ends (BSE).

Shaft sizes.